Motor Lubricant and the Proper Melting Point for Sewing Machine Motors

Are you using the right motor grease and lubricant for your Singer Featherweight? There are old, original tubes, new tubes and even some new kinds on the market... but are they properly suited for the Singer Featherweight? How would you know? Watch the video tutorial above and our old one below from 2015 or scroll down to read through Carmon Henry's 1st video tutorial in text format.

PART 1 from 2015, showing other grease comparisons above.

*We have now updated our Featherweight Shop Motor & Gear Lubricant video tutorial with a "Part 2" to reflect the new SEW-RETRO GreaseTM brand!

We are often asked if SEW-RETRO GreaseTM is appropriate for other vintage Singer Sewing Machine motors -- and the answer is yes - so long as your vintage Singer motor has motor ports with a felt wick inside. If you are unsure of this, then if your manual indicates that your vintage Singer motor requires motor lubricant, then SEW-RETRO GreaseTM will be perfectly suited for your machine.

*******************************************

Today I want to talk to you about motor and gear lubricant for the Singer Featherweight. There has been much discussion about what is the right type of lubricant to use for vintage and antique sewing machines, and especially in the Featherweight motor. So, I would like to clear up some of that information and also show you where, how and when to use SEW-RETRO GreaseTM as well as tell you about some exciting news and developments here at the Singer Featherweight Shop.

Original Singer lubricant from the era of the Featherweight is a basic non-flowing, low melting point grease. Non-flowing, meaning that it will generally stay where it is put, and low melting point meaning under low heat, the lubricant will gradually melt and be reduced to its basic lubricating properties.

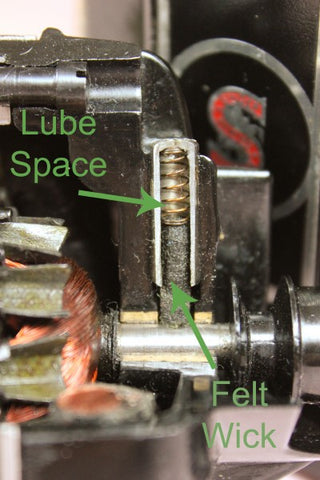

This is a cutaway view of the Featherweight motor that was given to me by Dave McCallum, and it offers an excellent view of where SEW-RETRO GreaseTM goes inside this motor. Most** all Featherweight motors have two lubricating ports, one on the top of the belt and one on the back of the motor. Inside each port is a felt wick as well as some space to hold the grease. When the motor is in use there is a small amount of heat that is generated, partially from the friction between the shaft and the bushing. This heat causes the low melting point grease to liquefy, wick through the felt onto the shaft of the motor. If the melting point is too high, however, the grease will either not melt at all or not flow through the wick unless the motor gets very, very hot - which is harmful to life and longevity of your motor.

(**Most White Featherweight machines do not require lubricant for the motor. You will know if your White Featherweight takes motor lubricant because it will have the lubricant ports on the motor itself.)

We have spent several years researching, testing, and having professional laboratory tests done on the original Singer lubricants in order to supply a grease that would match and meet the unique needs of those who collect and regularly use vintage and antique sewing machines. And, specifically for us here at the Featherweight Shop, we wanted a grease that would help quilters preserve their Singer Featherweights as they use their machines day-in and day-out to piece all their lovely quilts! Therefore, we are pleased to say that we finally have such a grease!! Originally, we called it the Featherweight Shop Motor & Gear Lubricant, but as of March 2018, we are rebranding it as SEW-RETRO GreaseTM to help all owners of vintage and antique sewing machines know that it is the best and safest product to use with your machines, including but not limited to the Singer Featherweight 221 and 222.

Let's learn about the importance of the proper melting point for a grease best suited for vintage and antique sewing machines.

Below is a snapshot of a simple heat and melting point tests to illustrate the melting points of a few of the sewing machine lubricants found today. We simulated the felt wick by placing several different lubricants on a thick felt mat, testing to see how fast they melted and wicked through the felt.

- Lubricant #1 is original Singer motor lubricant from the United Kingdom

- Lubricant #2 is our newly developed lubricant from the Singer Featherweight Shop.

- Lubricant #3 is Original Singer motor lubricant from the US.

- Lubricant #4 is new Singer lubricant in the red/white/pink tube.

- Lubricant #5 is a new white-colored Singer lubricant in the blue and yellow tube.

- Lubricant #6 is "Nova's" syringed lubricant.

- Lubricant #7 is Tri-Flow Grease.

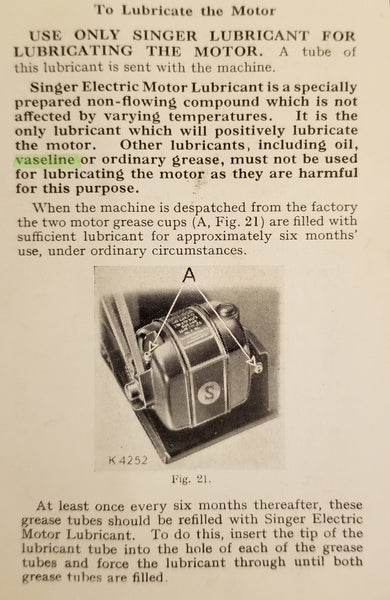

- Vaseline Petroleum Jelly test - review PART 2 of the video tutorial far above and do not put petroleum jelly in your motor whatsoever. It is a paraffin wax and actually has a body temperature melting point, which is way too low for your motor, and can actually cause damage to the electrical components internally. We occasionally hear through the "grapevine" that Singer used to recommend it - this is actually untrue. Here's an excerpt from an original Singer Featherweight Manual:

Singer lubricant was obviously a good motor lubricant according to original Singer standards, but new Singer grease made today isn't the same low-melting point formula that it once was. Excess heat is what destroys electric motors, so the cooler that you can keep a motor, the better its overall health, life, and longevity. Thus, as you can see from the time-lapse in the video above, that the melting point of our grease is within range of the original Singer lubricant from the U.K. You will notice that the melting point of our grease is less than other popular machine lubricants currently on the market. Lubricants #4 and #5 did eventually melt with a significant heat increase. Lubricant #5 left a white-ish zinc powdery residue behind which will clog the felt wicks, and both are considered harmful to the motor because of their higher melting points. #6 turned a yellowish-brown in color with the temperature increase, but it did not lose form nor did it melt - it actually started to smoke and burn like #7 did. Lubricant #7 did not change color, change shape or melt either. That is because #7 is Tri-flow grease and is not designed to melt at all. It will actually burn and smoke if the temperature is hot enough. Although Tri-flow is superior in its lubricating properties for places like gears, it is not properly formulated to use in the lube ports of vintage and antique sewing machine motors, including the Singer Featherweight 221 and 222.

*If you haven't already, be sure to watch PART 2 of the COMPARISON video which reflects the new SEW-RETRO GreaseTM brand and Vaseline petroleum jelly comparisons.

As you can see from the RPM demonstration in the video tutorial that the motor to handwheel revolutions improved after our grease was added. The ports were then heated with a hairdryer to get the lubricant flowing through the old dry wicks.

So, what does this mean if you have purchased other lubricants? Good question. The good news is that any of those lubricants will be perfectly suited for your sewing machine gears only, but we cannot recommend them at all for vintage and antique sewing machine motors. However, refer back to the time lapse portion of the video to learn how to clean out the old grease from the motor ports and apply the better suited and low-melting-point grease of SEW-RETRO GreaseTM - formerly known as the Featherweight Shop Motor & Gear Lubricant... remember, same Featherweight Shop Grease, just rebranded!

Keep in mind, that there is no cure for a machine motor that is worn out from lack of maintenance, but we might as well do all we can to keep these machines running strong into the future.

Featherweight Shop Motor & Gear Lubricant

is now rebranded as SEW-RETRO GreaseTM

SEW-RETRO GreaseTM is now available for sale by clicking here. It comes with a curved tip syringe that works perfectly for lube placement as well as being economical in that there is minimal waste. This application idea is not something I came up with on my own, but what I found to be the best application method from Ray White’s Advanced School on sewing machine repair. Thanks so much, Ray, for all your help!

Each motor lubricant comes with an instruction sheet. Page 1 shows how to apply it to the gears and page 2 shows how to clean the motor ports and then how to refill them.

If your machine has old grease on the gears, they should be cleaned first using Kerosene and a gear & lint cleaning brush - or an old toothbrush works, too. We put Kerosene in the same style bottles as our sewing machine oil so that you can direct the kerosene precisely on the point to be cleaned. You may order these long spouted empty bottles on our website as well.

Both the top and bottom gears should be cleaned at the same time. Therefore, it would be necessary to remove the spool pin coverplate and bottom drip pan together.

I recommend placing the machine on a piece of cardboard to catch and absorb the drips from the kerosene and dirty residue that flows while cleaning. Once the gears are clean, SEW-RETRO GreaseTM can be added by putting a bead of the grease on the gears and then slowly turning the handwheel. This will distribute the grease to the corresponding gear.

We do not recommend using fibrous paper cloths or cotton swabs, etc. to clean the excess grease away because this will introduce lint and foreign fibers into the gears. Instead, after turning the handwheel a couple of times manually, use your finger to wipe off any excess lubricant. Although the excess grease will not hurt anything it will leave a mess inside your machine.

Repeat this process to grease the bottom gears.

To lubricate the motor, it may be necessary to first remove old grease clogging the motor ports. Gently insert the port cleaning tool in each motor port and swirl it around to dislodge the old grease. (You can also use a Q-tip or hollow cotton swab, with both cotton swab ends clipped, as a replacement port-cleaning tool.)

Remove the cap from the lubricant and place the applicator tip at the motor port opening and begin filling the port with SEW-RETRO GreaseTM. Do not form a seal with the applicator tip or use force to push plunger - just place the tip of the applicator at the motor porthole and push a little bit of SEW-RETRO GreaseTM inside. You can see from our cut-away motor that the area to house the new grease is quite small and a little lubricant goes a long way. Remove applicator slowly while continuing to dispense SEW-RETRO GreaseTM in the port. Use your finger to wipe away any excess. Repeat this process for the other motor port.

Singer originally recommended lubricating the motor about every 6 months and the gears occasionally, as needed. This is our recommendation as well unless you are doing a lot of sewing, day-in-day-out. Then, perhaps once a quarter, or even once a month or even more often if free-motion quilting.

When you are finished lubricating the gears and/or motor, it may be necessary to pull back slightly on the plunger so that the SEW-RETRO GreaseTM is no longer under pressure. Then you can replace the cap to the tip and store without it leaking.

SEW-RETRO GreaseTM

(formerly known as the Featherweight Shop Motor & Gear Lubricant) is endorsed by fellow Featherweight expert, Dave McCallum!

Although SEW-RETRO GreaseTM was developed for us specifically for the Featherweight and other vintage and antique sewing machines, it can be used on the gears of any sewing machine with all metal gears. It should NOT be used on plastic or nylon gear systems.

If you own a quilt store or a Featherweight business and are interested in carrying SEW-RETRO GreaseTM, please feel free to contact us directly for wholesale inquiries.

As always, we look forward to keeping these Featherweight machines working long into the future and are here to help and offer Featherweight service and technical support. Feel free to contact us anytime.

*We have now updated our Featherweight Shop Motor & Gear Lubricant video tutorial with a "Part 2" to reflect the new SEW-RETRO GreaseTM brand!

******************************

Common Question: Where do I grease my white Featherweight?

So, returning to the question at hand, where do you grease your white Featherweight?