The Free-Arm Featherweight 222K and How It Differs From the Featherweight 221

The Singer Featherweight 222K Sewing Machine

(and the difference between a Singer 221 model)

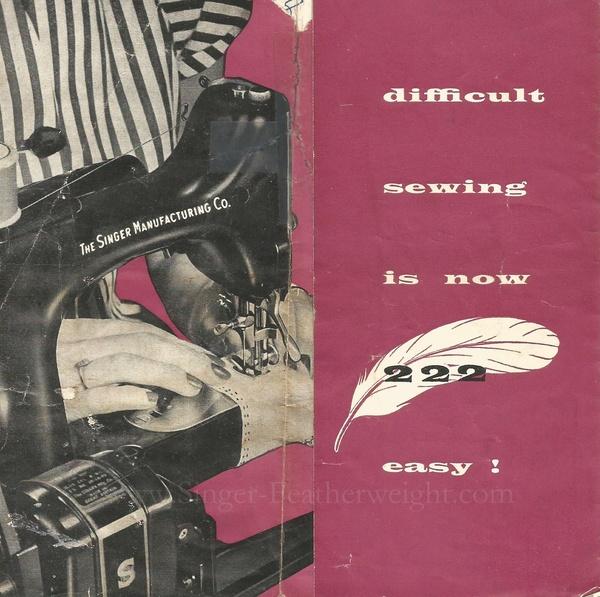

Approximately 100,000 222K Featherweights were made worldwide and are one of the best sewing machines ever made. Sometimes referred to as the "Free-Arm Featherweight" by those who are not familiar with the model 222K, these Singer Featherweight sewing machines were manufactured identically to the original 221 but with two additional and highly desirable features:

-

Convertible Flat Bed into Tubular Bed or Free-Arm

This very tiny free-arm allows for easier application of sleeves and cuffs or any hard-to-reach seaming.

-

Sew / Darn Lever

Feed dogs can be easily lowered, allowing free-motion embroidery and darning work.

Machine bed in place

Machine bed in place

Machine bed as it is being removed

Machine bed removed revealing the very narrow free-arm.

Feed-Dog Lowering Lever

Pulling the knob out, then lowing the lever will lower the feed dogs, enabling free-motion quilting and / or darning.

Compare the photo above with the photo below. The feed dogs (teeth-like mechanism) can be lowered for free-motion work on the 222K Free-Arm Featherweight. You will not need to cover the feed dogs like you would on the Singer 221 model or many other vintage Singer model machines.

The 222K would have had some extra attachments available as well. All 222K free-arm Featherweights had the unique embroidery foot originally included, but the embroidery hoop was a frequently added extra accessory:

All 222K Featherweights were manufactured in Scotland beginning in July 1953. Their engineering and design were more labor intensive, thus it was later determined by Singer that manufacturing them would not be as cost-effective and no longer marketable. Production ceased of all free-arm 222 Featherweights in 1961.

Today, ironically, the 222 Free-Arm Featherweight is considered one of the most highly collectible and desirable Singer Sewing Machines. This is why it is not uncommon to see them sell anywhere from three to eight times more than the average Singer 221 model (of course, varying on condition, inclusions, and seller reputability).

Another Subtle Difference:

The area around the presser bar lever is just slightly wider on a 222 than a 221. The 222 is only 1/16 of an inch wider, which is just enough to notice if you're going to try attaching a Single Thread Embroidery Attachment on your free-arm model Featherweight. You will need to have some patience when trying to get it in position on your 222K. (If you have the option, I would recommend using it on your 221 model Featherweight or other vintage Singer model. The 221 Featherweight allows a better and proper fit of the Single Thread Embroidery Attachment.)

Another Subtle Difference:

The area around the presser bar lever is just slightly wider on a 222 than a 221. The 222 is only 1/16 of an inch wider, which is just enough to notice if you're going to try attaching a Single Thread Embroidery Attachment on your free-arm model Featherweight. You will need to have some patience when trying to get it in position on your 222K. (If you have the option, I would recommend using it on your 221 model Featherweight or other vintage Singer model. The 221 Featherweight allows a better and proper fit of the Single Thread Embroidery Attachment.)

Collectible, yes - but certainly PRACTICAL!

The 222K Free-Arm Singer Featherweight is by far the best machine April has ever owned when it comes to practicality and usefulness Her 222K Featherweight has sewn numerous garments, alterations, repairs, quilt tops, and more. It sews the basic straight stitch for piecing any quilt top, yet easily converts to the free-arm to sew baby dress sleeves, odd-shaped seams and curvatures. and having the feed dogs out of the way makes darning repairs convenient and free-motion quilting a real treat!

Regarding the Motor:

The Featherweight 222 / 222Ks that we offer for sale are always electrically compatible in the USA and CANADA. That is, they run on 110 voltage or current. Internal motor and electrical components are all replace, rewound or electrically altered with original Featherweight parts compatible with North American electricity. All our 222K Featherweight machines go through an electrical-safety inspection and testing (of vital importance when making the upgrade), giving you the assurance that your sewing machine is safe for today's electrical standards. When purchasing a Singer 222 from us, you will not need to purchase a separate voltage converter. Just plug it in and sew!

However, if you purchase a Singer 222K abroad or one that still requires electrical current of 220 voltage, you will need to make the decision to either have it converted or simply purchase a separate voltage converter. If you opt to convert your machine, then you will need to either have the 220 volt motor rewound to 110, or purchase an original Featherweight 110-volt motor to replace it. The foot controller will need some adjustment and the light bulb will need to be changed to 110 volt as well. A vintage original Featherweight motor can cost well over $100, and yet it still will have all the old original wiring and no guarantee of how long it will last. A rewound motor (a service we offer), while the more expensive option on the front end, is like getting a completely brand new motor on the inside. This gives your motor supreme power and assures you of a strong running machine for years to come -- all while keeping the originality of your machine cosmetically. A voltage converter is the least expensive option and costs about $20-$30. Just make sure you get one that will handle a minimum of 100 watts. The downside to a converter is that it is a separate unit that must be kept with the machine.

However, if you purchase a Singer 222K abroad or one that still requires electrical current of 220 voltage, you will need to make the decision to either have it converted or simply purchase a separate voltage converter. If you opt to convert your machine, then you will need to either have the 220 volt motor rewound to 110, or purchase an original Featherweight 110-volt motor to replace it. The foot controller will need some adjustment and the light bulb will need to be changed to 110 volt as well. A vintage original Featherweight motor can cost well over $100, and yet it still will have all the old original wiring and no guarantee of how long it will last. A rewound motor (a service we offer), while the more expensive option on the front end, is like getting a completely brand new motor on the inside. This gives your motor supreme power and assures you of a strong running machine for years to come -- all while keeping the originality of your machine cosmetically. A voltage converter is the least expensive option and costs about $20-$30. Just make sure you get one that will handle a minimum of 100 watts. The downside to a converter is that it is a separate unit that must be kept with the machine.

Regarding the Case:

Most Featherweight 221 cases will not work with a 222 sewing machine. All Featherweight 222 Sewing Machines are just a fraction taller than a 221 preventing the lid from closing properly in most 221 cases.

Regarding the Manual:

The original manuals are very hard to come by as they were easily torn, lost or thrown out. It was a very thorough little handbook, though, with nearly 100 pages of instruction. If you do not have an original, you may download a free copy by clicking here.